opticon®

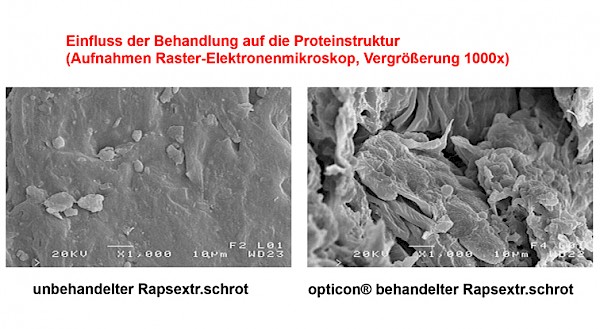

The opticon® process is a pressure hydrothermal process technology developed by Deutsche Tiernahrung Cremer. The patented process is used to refine individual and compound feeds. The opticon® process is a further development of the proven extrusion technologies in feed production. The high degree of material conversion achieved by the process technology is purely physical without the use of additives. Thus, using specific technical and physical parameters, protein feedstuffs such as rapeseed meal, soybean meal and sunflower meal are treated in such a way that the protein in the rumen of the dairy cow can be degraded to a lesser extent by the rumen bacteria. This significantly increases the bypass proportion of protein. This has advantages for the performance of the dairy cow, protects the environment through less protein in the daily ration and is also economically advantageous for the farmer.

opticon®: feed optimisation in seven steps

- Single feedstuffs such as wheat, barley or maize are sprayed in water vapour.

- This is followed by a short but intensive heating of the treated components.

- The resulting mass is kneaded and pressed.

- Another short but intensive phase of heating follows.

- The hot mass is crushed.

- The steam is released from the plant.

- The mass is specifically dehumidified and relaxed ("flash phase").

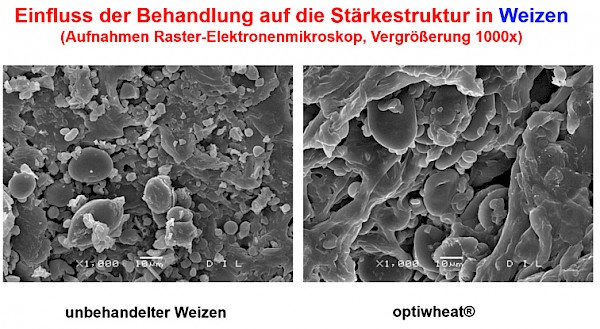

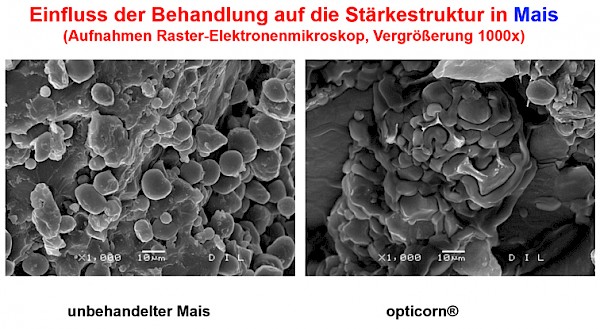

Another successful application of the opticon® process is in the refinement of cereals for feeding young animals such as piglets, chicks and calves. The structure of the carbohydrate skeleton in wheat, barley or maize is changed in such a way that the carbohydrate digestibility and thus also the stability of the microflora in the intestine is positively influenced. An important factor for performance and keeping the animal healthy in a natural way.

The patenting of the opticon® process was the logical consequence of our consistently pursued research programme, which deals with the optimisation and further development of feeds and their ingredients.

Improvement of feed quality - protection of the environment

Compared to known processes, the opticon® process requires significantly less energy to achieve a certain material conversion. Instead of the energy-intensive drying of the treated products, as is necessary in conventional extrusion, a targeted dehumidification takes place here in a relaxation phase ("flash phase").

This contributes significantly to the conservation of resources and gives the process remarkable environmental compatibility and high economic efficiency.

Optimised special feed for piglets and dairy cattle

The special feeds developed with the help of opticon® technology are mainly used for feeding dairy cows and piglets:

Protein-rich special feed for high-performance cows

deukalac UDP 39 is a rumen-protected, high-protein special feed for high-performance cows. It has excellent protein digestibility and high biological value. This is the prerequisite for top performance and high fitness of your dairy herd. Due to the pressure hydrothermal refinement of the initial mixture of high protein soya extraction meal (50%) and 00 rapeseed extraction meal (50%), our special product achieves a proportion of undegraded raw feed protein (UDP) of 60% of the total protein. This means that deukalac UDP 39 contributes to ensuring consistent quality and optimises milk production. The optimally balanced protein supply also makes a significant contribution to environmental protection.

- Find out more in theproduct flyer.

Tasty and highly digestible cereal package for piglets

optigrain® is a pressure hydrothermally digested cereal package for upgrading the farm's own mixtures for piglet rearing. It consists exclusively of wheat (50%), barley (25%) and maize (25%), refined using opticon® technology. optigrain® ensures maximum performance in piglet rearing thanks to its high starch digestibility - especially in phases of low enzyme activity. At the same time, it ensures an increase in water retention capacity ("dry" manure for clean crevices), an optimal nutrient supply and its excellent acceptance by piglets due to its characteristic smell and taste. Especially in the critical weaning phase, these properties can make all the difference.

- Find out more in theproduct flyer.

opticon® products for feed production

Feedstuffs optimised with the help of the opticon® process are ideally suited as valuable components of modern, highly digestible and digestible compound feeds. Our deuka Feed Ingredientsdivision is responsible for marketing and selling these special products to our business partners in the feed industry.