Deutsche Tiernahrung Cremer optimises all piglet feeds nationwide

Towards sustainable success in piglet rearing

For the 2022 harvest Deutsche Tiernahrung Cremer optimises the piglet feeds of its deuka and Club brands. Extensive studies show an improvement in feed conversion Feed conversion and an increase in daily piglet gains. For the first time, an enzyme ferment is also used in the piglet segment during the comprehensive adaptation of the recipes. The changeover of the piglet rearing feed recipes (FAZ I-III) takes place in August in all plants nationwide.

"Sustainable success in pig farming - today this is more important than ever. It all starts with efficient feeding of the piglets. The focus is on optimal vitality, best feed intake, effective feed conversion and thus high daily gains. Our optimised piglet feeds achieve all this," says Georg Riewenherm, Head of Product Management at Deutsche Tiernahrung Cremer. "For piglet producers, this means many things at the same time: increasing the performance of the herd, reducing unnecessary excretions and improving economic success. In this way, we contribute to sustainable piglet production - today and in the future

Enzyme ferment, polyphenols, phytogens: three components optimise piglet feeds

Three adjustments are at the heart of the recipe optimisation. The most important innovation is the inclusion of an enzyme ferment. This is a by-product of solid-state fermentation that contains high levels of a wide variety of enzymes. The enzymes increase nutrient and protein availability in piglets. The prebiotic effects they cause also have a positive effect on the microorganisms in the intestine and thus increase the well-being of the young animals. A similar product has already been successfully used by Deutsche Tiernahrung Cremer in sow feeding for many years.

Another innovation is the addition of polyphenols. These are secondary plant substances that belong to the group of antioxidants. Polyphenols contribute to the protection against oxidative stress, which occurs in piglets due to weaning stress, feed change, ranking fights or infections. Possible consequences are reduced performance and intestinal problems. The plant substances bind free radicals and thus reduce stress at the cellular level and its consequences.

Finally, all piglet feeds in the future will contain phytogenic additives. These additives are plant substances that stimulate appetite and aid digestion. They occur naturally in oregano, fennel and aniseed, for example.

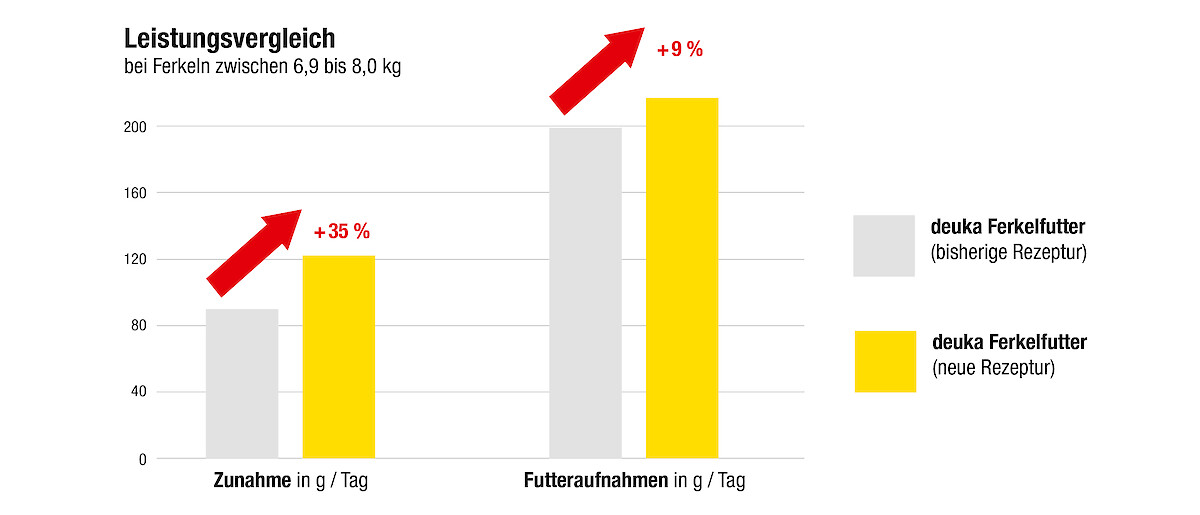

Practical studies show improved feed conversion and daily gains for piglets

The economic advantages of optimising the deuka piglet concept are proven by two studies carried out on practical farms. Feeding was compared with the previous and the optimised recipes (1). The studies showed an increase of 20 g in daily gain per piglet. In the group of piglets between 6.9 and 8.0 kg, the increase in daily gain was as much as 35 percent (see graph).

At the same time, the average feed conversion rate improved from 1.52 kg feed per kg weight gain to 1.47 in the weight range between 6.9 and 22.0 kg. This corresponds to a reduction of just under 3.5 percent. Extrapolated to an average farm with just under 1,500 piglets, the feed quantities are thus reduced by over 1,100 kg per run (up to 22 kg piglet weight). If piglets weighing up to 28 kg or heavier are reared, a feed saving of over 1,600 kg can be assumed.

About Deutsche Tiernahrung Cremer

Deutsche Tiernahrung Cremer is the market-leading compound feed producer in Germany. With

2.5 million tonnes per year (2021), the company is the largest private producer of high-quality compound feeds for livestock and pets. More than 725 employees from 20 nations work successfully at 13 locations. The plants are among the most modern and largest of their kind in Germany. The deuka brand is of great importance throughout Germany and is also represented in many neighbouring European countries. The associated brands Club and Nordkraft are firmly established, especially in southern Germany and Lower Saxony. They all stand for the highest quality in all feeding areas.

Deutsche Tiernahrung Cremer, based in Düsseldorf, is a company of Peter Cremer Holding GmbH & Co KG, Hamburg. The company looks back on almost 100 years of tradition in compound feed production.

You can find out more about our company, our products, feed concepts and brands at www.deuka.de

(1) On test farm no. 1, the piglets were fed deuka primo start on the sow and then 10 kg deuka primo safe until weaning. On test farm no. 2, the experimenters fed deuka primo wean to the sow, deuka primo start after weaning and then 11 kg deuka primo safe until weaning. The duration of the feeding was 36 days.

Contact person

Downloads

Documents

Picture material

-

Fodder illustration_Pellet pile_RGB_© Deutsche Tiernahrung Cremer

2.7 MB -

Forage display_Pellet pile_CMYK_© Deutsche Tiernahrung Cremer

2.8 MB -

Sow illustration_Fork feed sacks_RGB_© Deutsche Tiernahrung Cremer

787.7 kB -

Bag illustration_Pig feed bags_CMYK_© Deutsche Tiernahrung Cremer

12.2 MB -

Graphic_performance_comparison_practice_examination_RGB_© Deutsche Tiernahrung Cremer

341.6 kB -

Graphic_Comparison of services Practice investigation_CMYK_© Deutsche Tiernahrung Cremer

868.5 kB

Downloads

Documents

Picture material

-

Fodder illustration_Pellet pile_RGB_© Deutsche Tiernahrung Cremer

2.7 MB -

Forage display_Pellet pile_CMYK_© Deutsche Tiernahrung Cremer

2.8 MB -

Sow illustration_Fork feed sacks_RGB_© Deutsche Tiernahrung Cremer

787.7 kB -

Bag illustration_Pig feed bags_CMYK_© Deutsche Tiernahrung Cremer

12.2 MB -

Graphic_performance_comparison_practice_examination_RGB_© Deutsche Tiernahrung Cremer

341.6 kB -

Graphic_Comparison of services Practice investigation_CMYK_© Deutsche Tiernahrung Cremer

868.5 kB