Interview with the compound feed magazine "De Molenaar

Holistic approach to feeding benefits customers in Benelux

In Germany and the Benelux countries, the agricultural sector is facing major challenges. These include limiting nitrogen emissions, droughts and falling sales prices, as well as the consequences of the Corona crisis. The compound feed manufacturer Deutsche Tiernahrung Cremer is responding to current developments with its own holistic approach to animal nutrition and supply. Managing Director Dr. Heinrich Kleine Klausing and Matthias Kleverbeck, Sales Manager for opticon® special products, explain the offer for compound feed producers and farmers in the Benelux countries in an interview with the Dutch compound feed magazine "De Molenaar".

The current challenges facing agriculture are enormous. Meeting them requires the willingness of all players in the compound feed industry to adapt their existing processes to the circumstances and to develop new products that meet the needs of modern farms. The central condition for this is a critical view of the challenges facing farmers today and in the future. Deutsche Tiernahrung Cremer - better known on the market as deuka - takes a holistic approach to this: modern supply concepts tailored to existing requirements based on specially processed feed components that are used on a farm-by-farm basis. The focus is on high-quality, pressure-hydrothermally treated individual feed components as well as tailor-made special feeds for cattle and pig farmers.

Dr Heinrich Kleine KlausingOptimally supplied, healthy and satisfied animals are the condition of a low excretion, emission-reduced and thus sustainable animal husbandry.

Farm-specific solutions for a wide range of challenges

"To ensure that cattle and pig farms can comply with all the strict requirements and that conventional livestock farming still has a future tomorrow, feeding is becoming more and more the focus of attention as a significant farm input," says Dr. Heinrich Kleine Klausing, one of the managing directors of Deutsche Tiernahrung Cremer (Product Concept / Mineral Feed division). "The condition of low excretion, emission-reduced and thus sustainable animal husbandry is optimally supplied, healthy and satisfied animals. To achieve this, farmers need more than ever a strong partner in the industry who can supply them with precisely tailored feed solutions. As an experienced and value-driven feed manufacturer, we are committed to this very goal."

Special pressurized hydrothermal products as a component of holistic animal nutrition

To this end, the company offers a wide range of services and products - above all functional feed components - for compound feed companies. The basis of the highly digestible pressure hydrothermally treated special products is opticon® technology.

Matthias KleverbeckMany customers in the industry are already using opticon®-treated products to develop feed concepts with specific feeding targets, especially for pigs and cattle.

"A key to maximizing performance, improving animal health, and minimizing excretions (e.g. nitrogen) and emissions is the optimal utilization of feed in the animals' stomach and intestines," says Kleverbeck. "For this purpose, we have developed the patented pressure hydrothermal opticon® technology. It is used to break down raw materials for better digestion. opticon® is a further development of the proven extrusion technology. Many customers in the industry are already using opticon®-treated products to develop feed concepts with specific feeding targets, especially for pigs and cattle."

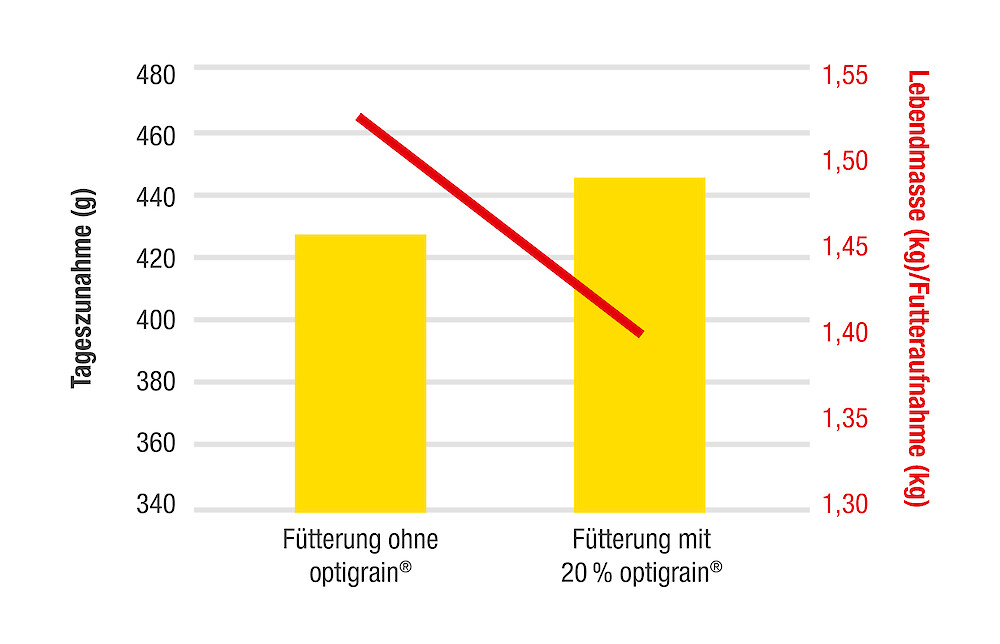

The opticon® process offers many advantages for the development of feed concepts for pigs and cattle. Treated cereals have a particularly high degree of digestion of the starch they contain of over 80% (determined by the amyloglucosidase method commonly used in the Netherlands with a 30-minute incubation period). Such digested feed components are particularly easy to digest. Due to their optimum dissolving behavior in the stomach, the feed slurry is mixed rapidly. This promotes optimum digestion in the intestine. This optimized feed utilization leads to an increase in the average daily gain of piglets, as impressively demonstrated in feeding trials (see following figure). The special "cookie smell" makes feed containing opticon® products particularly palatable."

Optimal fermentation properties for efficient digestion.

Depending on whether the raw materials treated with opticon® are used in cattle or pig feeds, they produce different, beneficial effects. "By refining rapeseed meal using the opticon® process, the proportion of undegraded dietary protein (UDP) can also be increased in dairy cattle feeds. This is done by purely physical means - without the use of additives such as formaldehyde," explains Kleverbeck. "A high proportion of the bypass protein UDP improves the supply of the animals and thus their performance. Forages with a high UDP content (such as the protein supplement deukalac NG UDP 33) are therefore ideal for covering the protein and amino acid supply of dairy cattle. Such feeds are used primarily to close supply gaps and during peak demand periods such as the start of lactation."

Fiber digestibility can also be improved with the aid of the pressure hydrothermal process. This is particularly relevant for sow and piglet feeding. If soybean hulls are refined using opticon® technology, the fiber structure is broken up. This not only improves the swelling capacity, but also the water-binding capacity subsequently increases. Finally, the treatment optimizes the fermentation properties of the processed component in the large intestine. The additional fermentation of the fiber makes an essential contribution to high intestinal health. The butyric acid formed during colon fermentation stimulates the growth of intestinal villi. Better and more efficient digestion is the result. Appropriately treated soy hulls in NON GMO quality - marketed under the name "FaserGold" - make a valuable contribution to the stomach and intestinal health of piglets and sows."

Dr Heinrich Kleine KlausingThe right advice is no less important to us than the development of innovative products.

Individual advice for tailor-made use

"Our special feeds and the optimized components used to produce modern high-performance feeds are at the heart of our holistic feeding strategy. After all, even the highest-quality feeds fail if they are not used adequately. For this reason, the right advice is no less important to us than the development of innovative products," explains Dr. Kleine Klausing. "As a family business, personal contact with our customers in agriculture is particularly important to us."

"In order to be able to take the individual situation on the farms into account in the best possible way, we work intensively with local feeding experts in Belgium, Luxembourg and the Netherlands who know the country and its people inside out," says Dr. Kleine Klausing.

Mr. Matthias Kleverbeck is responsible for the distribution of all specialties to customers in the compound feed industry. His colleague Kees Hoogendoorn is responsible for business with Dutch farmers.

Contact person

Matthias Kleverbeck

Contact person